CNC

The aesthetic design in combination with the ultra-flat panel characterizes the machine concept of the future.

The 19-inch vertical display – (smart phone like) multi-touchTouch operation offers you the highest level of operating comfort.

The M8V Series features a 19-inch vertical display. The screen is divided into two different display windows that can individually display a software keyboard, document viewer or other applications.

Find out more

Drive Technology

This architecture enables a faster position interpolation cycle and synchronization between drive units, resulting in further high-speed and high-precision machining.

All operations from program values to servo commands are done in Nanometre (nm). Interpolation is at the Nanometre level even when the program command is at Micrometre (μm) level.

All these is the basis for new productivity-enhancing functions, such as OMR-FF control (Optimum Machine Response-Feed Forward), which allows the response to be set independently of the over speed control. This results in less vibration and therefore higher accuracy at higher speeds.

Find out more

Software

The NC Trainer2 plus supports customer-specific development; it helps with the creation of the ladder program for the user PLC by the manufacturer and the debugging and functional testing of the customer-specific screen pages.

Create/Check NC programs, perform setup and machine operations and output NC programs all via a personal computer. This software allows total personal computer-based CNC operation training and program reviews without having to use an actual CNC.

Multiple users can use the software simultaneously via a single network-connection license key. Well Suited to Group Training

Customize the operation panel, create and debug programmable logic controller (PLC) programs, make alterations to customized screens and output various data such as parameters or tool data all using a personal compu

Find out more

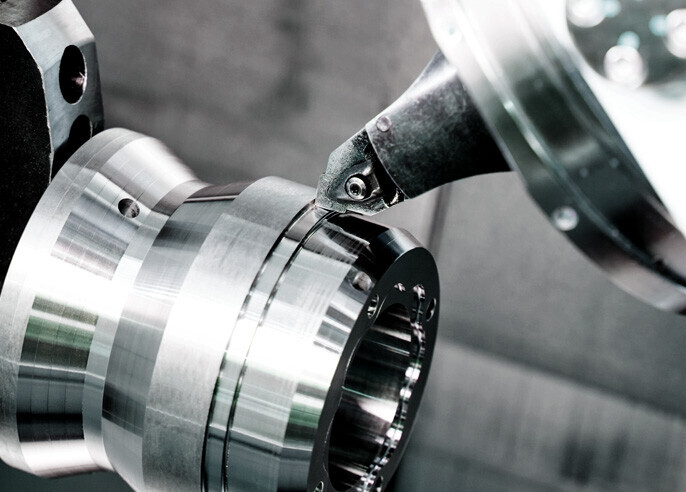

Lathe

Multi-axis multi-part system control features help to reduce cycle time and maintain synchronization between part systems.

M800/M80 Series provides “Spindle superimposition control, “a feature that enables simultaneous execution of turning and center tapping, although they needed to be executed individually. These features are effective in eliminating idle time, resulting in a significant reduction in tact time. This CNC also offers features that maintain synchronization between part systems, which is required for automatic lathes, in particular. These enable operators to implement ever more complex machining safely and securely.

Find out more

Milling

M800/M80 Series offers SSS 4th-generation (SSS-4G) control, enabling high-speed, high-accuracy, high-quality machining. SSS-4G control provides features that are effective in reducing tact time, including optimal acceleration/deceleration suited to each axis’ characteristics.

In addition, SSS-4G is capable of reducing machine vibration during high-speed cutting. SSS-4G control allows for greater cutting accuracy in the same length of time, or shorter cutting time with the same degree of accuracy when compared to our previous models.

Find out more

Robot Integration

The CNC functionality “Direct Robot Control” was developed so that robots and machine tools can work even closer together in the future and productivity can increase as a result. With the Direct Robot Control from Mitsubishi Electric, industrial robots can be integrated into the current CNC control series.

Thanks to the new function, commissioning can be carried out significantly faster and training and specialist requirements are also significantly reduced. Even with small lot sizes, companies can benefit from the new flexibility for their own production.

Plug & Play solution – connection between CNC and robot via Ethernet

Programming / teaching / operating the robot via G code through an additional menu on the control

Easy integration of the robot

Find out moreFields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch.

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Tel.: +49 (0)2102 / 486 - 0

Fax: +49 (0)2102 / 486 - 1120

cnc.sales@meg.mee.com

Benjamin Buzga

CNC Sales & Business Development Manager