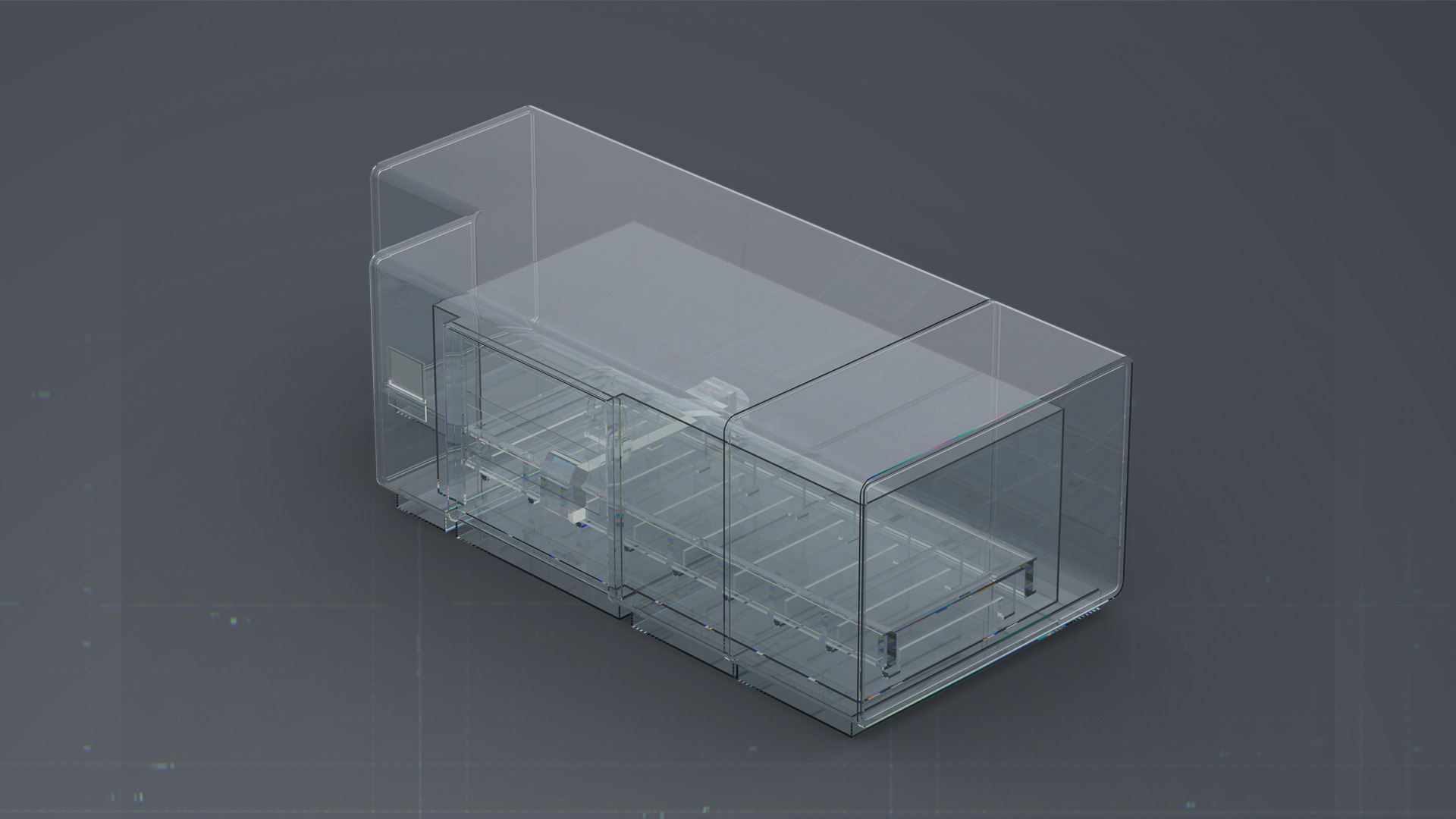

Specialized for various laser machining processes: Our M8V Control – flexibel and independently of the oscillator manufacturer.

– The Mitsubishi Electric CNC Engineering Team

Fly Cutting

Height Control

Dross Reduction Control

Fly Cutting enables laser beam to be turned on and off without stopping axes by comparing the command position in the program and the feedback position obtained from the motor-end encoder. Axes do not need to be stopped while processing, unlike in typical processing, in which the laser beam needs to turn on and off after axes are stopped at the start and end points of processing. This speeds up processing.

Height control is designed to keep the constant distance between a laser head and the work piece based on a value detected by an external non contact height sensor. To increase the machining accuracy it is important to machine the work piece within specific focal range of the laser beam. By compensating the NC position command in the drive unit, a constant distance between the surface of the work piece and the laser head can be kept, even if the surface of the work piece is uneven.

Dross Reduction Control automatically adjusts the laser processing conditions (laser power, frequency, duty) according to the processing speed. It raises laser power when the processing speed is high, and lowers it when the processing speed is low. This helps distribute the energy the workpiece receives from laser irradiation uniformly between the constant speed area and the deceleration area, reducing dross formation.

Flexible integration of any laser source, regardless of manufacturer, is possible. The laser oscillator can be controlled by means of the FCU8-DX522 laser I/F unit. This controls the laser processing conditions and the switching on and off of the laser beam.

The power of the laser oscillator is controlled by the CNC with pulse width modulation commands. The pulse width modulation commands are adapted to the laser processing conditions, laser power, frequency, duty cycle, and transmitted to the laser oscillator. Thus, the material and thickness of the workpiece can be taken into account in the machining process.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Tel.: +49 (0)2102 / 486 - 0

Fax: +49 (0)2102 / 486 - 1120

cnc.sales@meg.mee.com

Claudia Wonneberg

Sales Engineer CNC